APR REVERSIBLE VIBRATORY PLATES

Customer input plays a crucial role in developing the features that are built into all Ammann products, including APR Vibratory Plates. Customer requirements include a small compactor that still delivers an abundance of power; manoeuvrability; and operator protection against excessive hand-arm vibrations.

A range of options boosts versatility and enables the use of the APR plates in multiple applications.

Ammann plates are great fits for rental houses because of their extended service intervals – and because rental customers love their power, ease of operation, production and easy transport. Many of the plates are available with diesel or petrol engines, too.

Ready to learn more? Click on the product hotspots or the chat contact.

APR REVERSIBLE VIBRATORY PLATES

Ease of use

Low-vibration guide handle

A technologically advanced guide bar suspension significantly reduces hand-arm vibration, making the system safer and more operator-friendly. Health risks such as hand-arm vibration syndrome, also known as “white finger,” are so low that safety codes do not require documentation of hours when working with the plates.

Hydrostatic steering control

Hydrostatic forward and reverse steering enables quick directional changes and compaction in tight spaces. The continuously variable drive control allows the operator to adjust the working speeds to suit ground conditions, ensuring productivity and safe operation of the machine. The drive control also provides on-the-spot compaction in particularly challenging areas.

APR REVERSIBLE VIBRATORY PLATES

Built-in durability

Ammann plate compactors are built to last. A robust frame protects the machine and a base plate sheds materials that can cause damage. A well-thought-out design offers easy access to service points, so your crew can quickly complete the life-extending maintenance that keeps the machines up and running.

A new, enhanced machine frame protects all key components on the jobsite. The frame also prevents damage from vibration. Contractors and rental businesses appreciate these pro-active precautionary measures.

Long life base plate

Wear-resistant base plate ensures long life. The self-cleaning design sheds loose materials that can cause damage.

Maintenance-friendly twin-shaft exciter

Extends service intervals and machine life.

APR REVERSIBLE VIBRATORY PLATES

Productivity for every situation

Superior compaction performance

The specially designed twin-shaft vibratory system generates high amplitudes that create exceptional compaction output. This performance enables the plates to work on varied materials and on jobsites where productivity is a priority.

Built-in efficiency

The hydrostatic steering concept allows Ammann APR Plates to compact “on-the-spot” for concentrated compaction in particularly challenging areas. The machine essentially hovers – no forward or reverse movement is required – while providing maximum compaction output that enables quick results.

APR REVERSIBLE VIBRATORY PLATES

Unmatched power & speed

Unmatched speed

The plates are designed for productivity. A balanced base plate combines with the twin-shaft vibratory system for evenly distributed compaction power. These key features provide Ammann’s renowned compaction punch and industry-leading working speeds, ensuring that all models deliver high productivity. The base plate is built to shed loose material, which keeps the machine clean and efficient and prevents soil and aggregate from accumulating and damaging the machine.

Powerful engine

Highly efficient engines provide the needed power. Most models are available with diesel or petrol engine - leaving the choice up to the preferences of the customer.

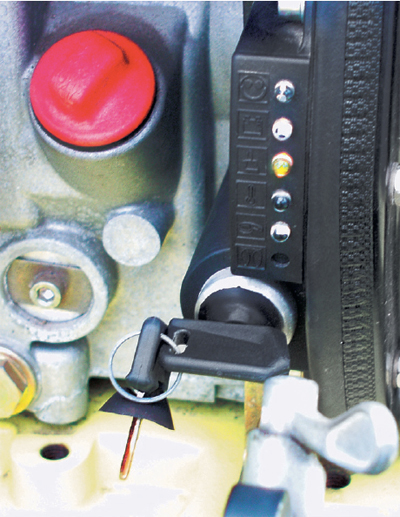

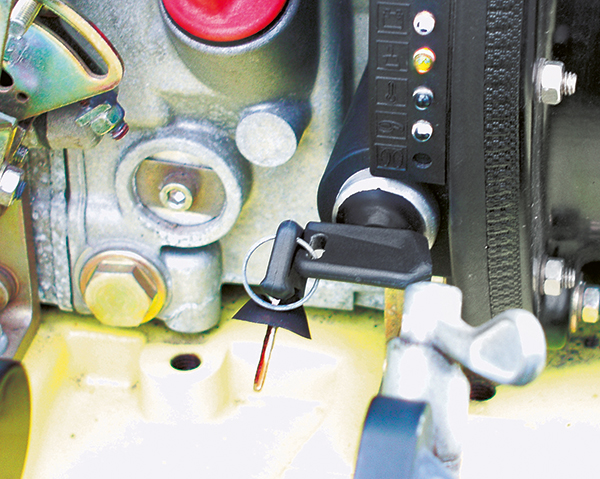

Easy to start

Each machine features two starting systems. The electric start version gets the plate up and running quickly, while a securely stored hand crank is available as a backup.

APR REVERSIBLE VIBRATORY PLATES

The right fit on your jobsite

The line of APR Reversible Vibratory Plates, engineered to be extremely productive on varied jobsites, is among the fastest in its class. The plates are reliable performers, even when working on difficult terrain and with challenging materials. A wide range of options provides versatility. The plates can switch between soil and asphalt compaction in minutes.

Rockfill/soil

The varied vibratory plate sizes ensure there is a machine that can conquer every challenge. Exceptional power and fast working speeds make the plates ideal tools for compacting loose material.

Asphalt

An optional water tank with sprinkling system on the APR 22/40, APR 25/40 and APR 25/50 prevents sticking and makes the plates a great fit for asphalt applications.

Paving stones

The plates can be equipped with optional paving pads on the jobsite. Installation is quick without the need for a single tool.

APR REVERSIBLE VIBRATORY PLATES

Simplified maintenance

Thoughtful placement of all service and maintenance points offers operators and technicians easy access. Downtime is minimised by robust machine design, a wear-resistant base plate and exceptional accessibility from all sides.

Protective frame and covers

A new, enhanced machine frame protects all key components on the jobsite. The frame also prevents damage from vibration. Contractors and rental businesses appreciate these pro-active precautionary measures.

Toolless daily inspections

Access to all daily inspection points is effortless, and fluid indicators are easy to view. No tools are required to access daily service points, ensuring the maintenance is completed quickly.

APR REVERSIBLE VIBRATORY PLATES

Transport made easy

Secure transport

All new plates are equipped with lifting and tie-down points that are based on European Rental Association (ERA) guidelines.

The tiedown points make securing the machine fast and easy, ensuring success so that risks are minimised. A central lifting hook is integrated into the frame.

Foldable handle

The advanced guide handle does more than prevent operator vibration – it also folds neatly to avoid damage during transport.

APR REVERSIBLE VIBRATORY PLATES

Optional equipment

Electric starter

APR models with a diesel engine can be equipped with an optional electric starter for an effortless beginning to every shift.

Hours-run meter

The next service date can be scheduled well in advance thanks to a continuous display of hours run.

Transport wheels

Permanently installed transport wheels are available for APR 2220, APR 2620 and APR 3020 models. The wheels are mounted in a safe position behind the plate and easily unfold beneath the machine when needed.

Water sprinkler

Water tank and sprinkler bar prepare the machine for action on fresh asphalt. The water prevents the asphalt from sticking on the plate. A control on the handle enables sprinkling to be changed (front/back), minimising water usage and extending intervals between fillings.

APR REVERSIBLE VIBRATORY PLATES

ServiceLink

Delivering the Data that Matters!

Ammann ServiceLink is a digital data management tool that provides customers with the information they want the most: machine location, battery status and operating hours. Data transfer is automatic thanks to new hardware, and access to the information is only a click away.

Manage your equipment – anytime, anywhere – with Ammann ServiceLink. This comprehensive fleet system provides key data for light compaction equipment, heavy compaction machines and asphalt pavers. You can choose which machines to track.

Highlights

- Supplies machine location, operating hours, battery status

- Provides one-click access to data

- Reliably transmits data from machines, no matter where they are

- Compatible with all machines produced by Ammann or other manufacturers

- Streamlines fleet upgrades (retrofit option)

- Easy to install

The hardware is easy to add as a retrofit

Simply attach the TCU and the battery to the machine. The TCU is activated when plugged into the battery. That’s it!