ARR 1585 TRENCH ROLLER

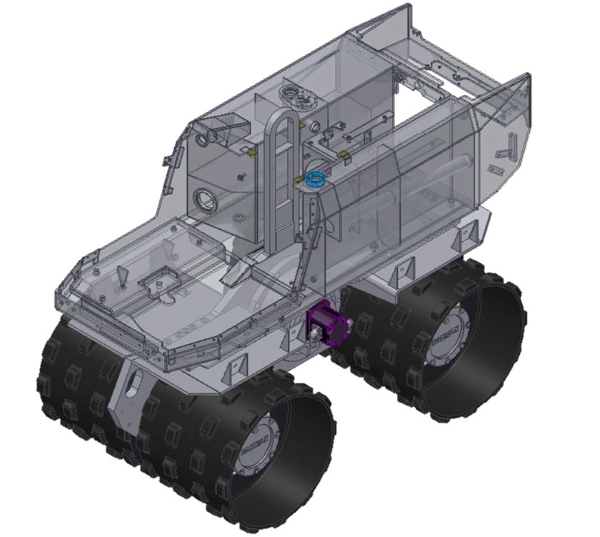

The vibratory system, centrally positioned between the front and rear drums, generates the high compaction force needed on the most challenging jobsites. The rigid-frame and skid-steered operation help operators succeed in all settings.

Durable components and the maintenance-free vibratory system minimise ownership costs.

Ready to learn more? Click on the product hotspots or the chat contact.

ARR 1585 TRENCH ROLLER

Controls

The rollers can be operated via onboard drive levers, a cable remote or an infrared remote control. A machine can be equipped with all three, giving the operator options based on the jobsite.

Having these options available is particularly popular with rental fleets.

ARR 1585 TRENCH ROLLER

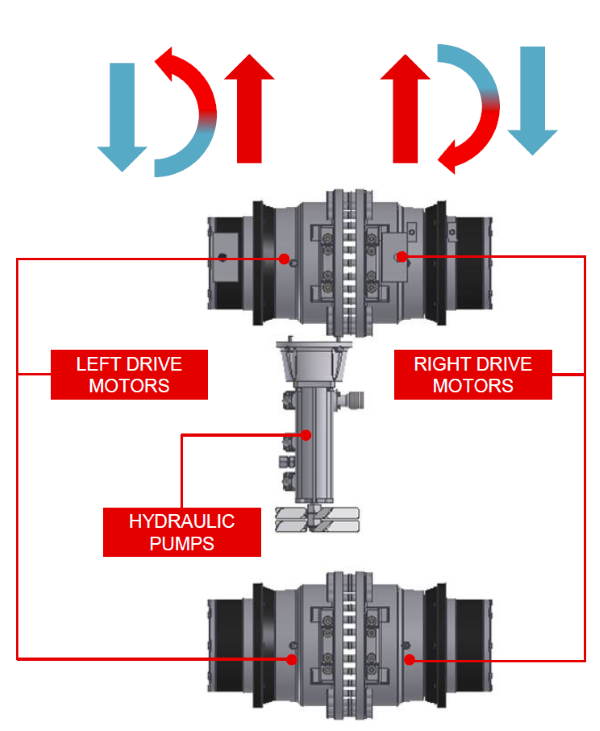

Skid-steer concept

The skid-steer concept with independent drum steer control brings unique manoeuvrability. The machine offers 360° "on-the-spot" turning for productivity in tight spaces – and operator comfort, too.

ARR 1585 TRENCH ROLLER

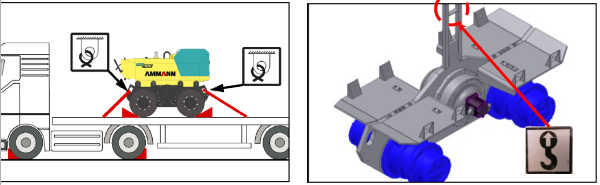

Central lifting hook

The central machine lifting point is conveniently located and easy to reach.

ARR 1585 TRENCH ROLLER

Engine

Meets the latest emission standards.

ARR 1585 TRENCH ROLLER

Maintenance-free parts

Heavy-duty components extend machine life and minimise the need for replacement parts. The complete vibratory system is maintenance free. This greatly reduces ownership costs by eliminating the need for replacement parts and saving time spent on machine maintenance.

ARR 1585 TRENCH ROLLER

Excellent traction

Four drive motors in each drum, combined with easy directional changes of the exciter, bring additional power to the drive system – crucial in challenging conditions. Drums provide well-balanced weight distribution and a low centre of gravity that helps the machine excel on slopes and uneven surfaces.

ARR 1585 TRENCH ROLLER

Variable working widths

Drum extensions enable varied working widths 630 mm (24.8 in) or 850 mm (33.5 in). This innovative solution is appreciated by rental fleets, which can meet varied needs with a single machine.

ARR 1585 TRENCH ROLLER

Protective frame and covers

All components are securely mounted to the frame and fully isolated from vibration. The robust machine construction provides durability and prevents damage to components on even the toughest jobsites.

ARR 1585 TRENCH ROLLER

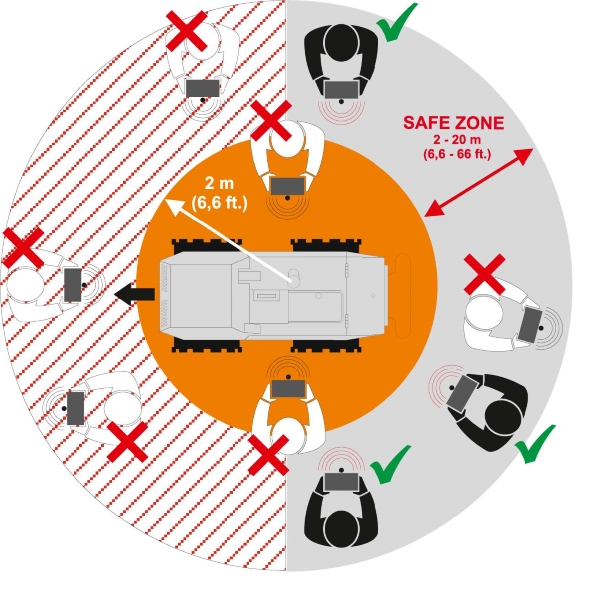

Infrared remote control

The infrared remote control is ergonomic, robust and waterproof. The control won’t engage unless the operator has direct visibility of the machine, maximising jobsite safety.

ARR 1585 TRENCH ROLLER

Operator protection

An integrated dead man’s handle protects the operator when working in narrow spaces, close to walls and in other potentially dangerous situations. In addition, all drive levers are equipped with a resetting function. Levers are automatically returned to the neutral position when the operator cannot control them.

ARR 1585 TRENCH ROLLER

High compaction output

The central vibratory system supplies industry-leading compaction output that makes the machine an invaluable tool on the jobsite. The high centrifugal force ensures effective results on varied jobsites and helps the crew reach density targets in fewer passes.